Call us :

- O2O7 112 9 118

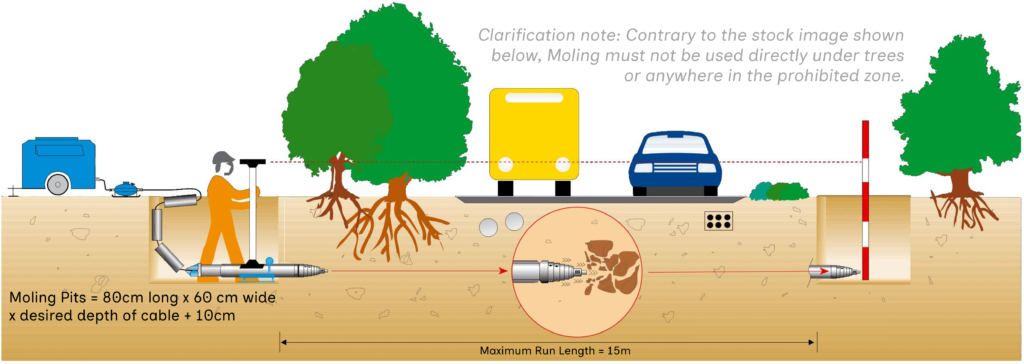

Moling relies on pits being dug at the beging and end of each run (a maximum of 15m apart). Once the mole reaches the target pit, it is detached from its air supply hose, which is then used to pull a conduit/pipe through the newly created tunnel.

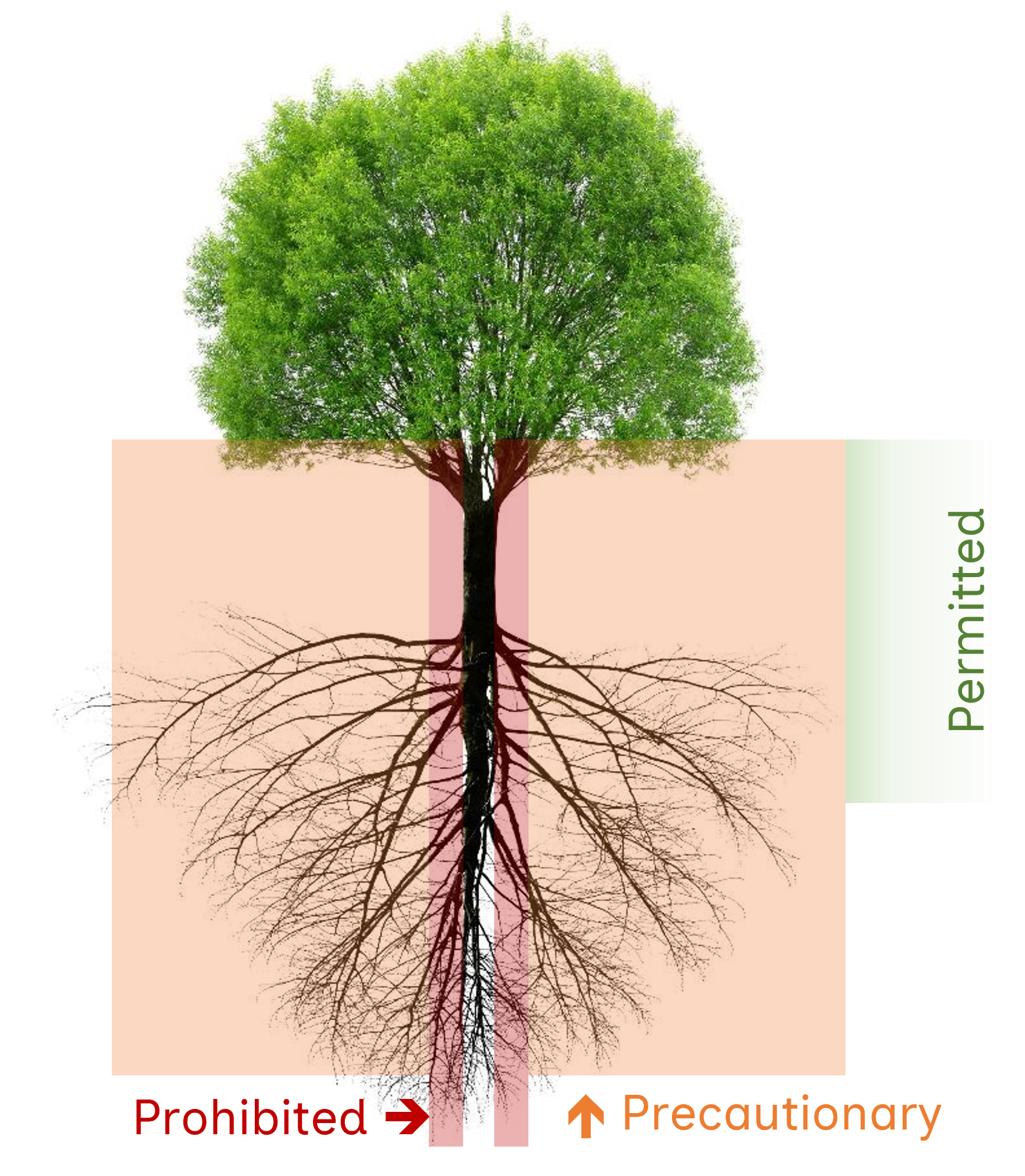

The vast majority of Garden Squares are impacted by Tree Preservation Orders, that impact the works that may be taken in/around trees or its roots, with clear guidance given in BS5837 trees in relation to design, demolition and construction.

Too many contractors will fail to account for Tree Roots when planning service routes, crossing too close to the Prohibited zone of each tree. Worse still many contracters will use Trenchinging Machines that are not approved for use in either the Prohibited or Precautionary zone.

Impact Moling is an approved “Trenchless Method” for running services in the Precautionary Zone of Trees where crossing said zone is unavoidable. Moling Pits are traditionally hand-dug, to avoid the use of any tracked machinery in/around trees, which would require further mitigation steps such as compression matts and heras fencing.

Impact moles are essentially a self-hammering/propelling missile, powered by compressed air. For works we bring a small, single tool air compressor, which is maneuverer around the site by hand.

Works start by planning the location of Moling Pits, with no more than 14 meters between each pit.

After the first two pits have been dug, Moling can start. A marker pole is placed in the target pit, with a “sight” placed on top of the mole in the starting pit. The mole is slowly propelled into the ground, with the sight used to check and adjust direction with regards to the target marker.

Once the operator is confident the mole is correctly align to the exit pit, it is left to run, progressing at a speed of roughly 1 meter every 3 minutes.

After successfully reaching the exit pit the mole is disconnected, and its supply hose used to pull conduit/piping back through the newly created tunnel.